Características del producto

√Alta precisión

√Materiales de alta calidad, fabricados en acero de alta resistencia, templado.

√Buena resistencia al desgaste, el templado aumenta la dureza de la superficie de la cremallera.

√Tratamiento térmico estable, puede adaptarse a diferentes entornos de trabajo.

√Fácil de instalar

√Gran adaptabilidad, se puede utilizar con varios tipos de engranajes, servomotores y sistemas de accionamiento.

√Varias especificaciones disponibles

Parámetros de especificación del bastidor lineal DIN 8

Haga clic en el botón de descarga para obtener la hoja de especificaciones del bastidor lineal DIN 8.

Specification

| Specification | Value |

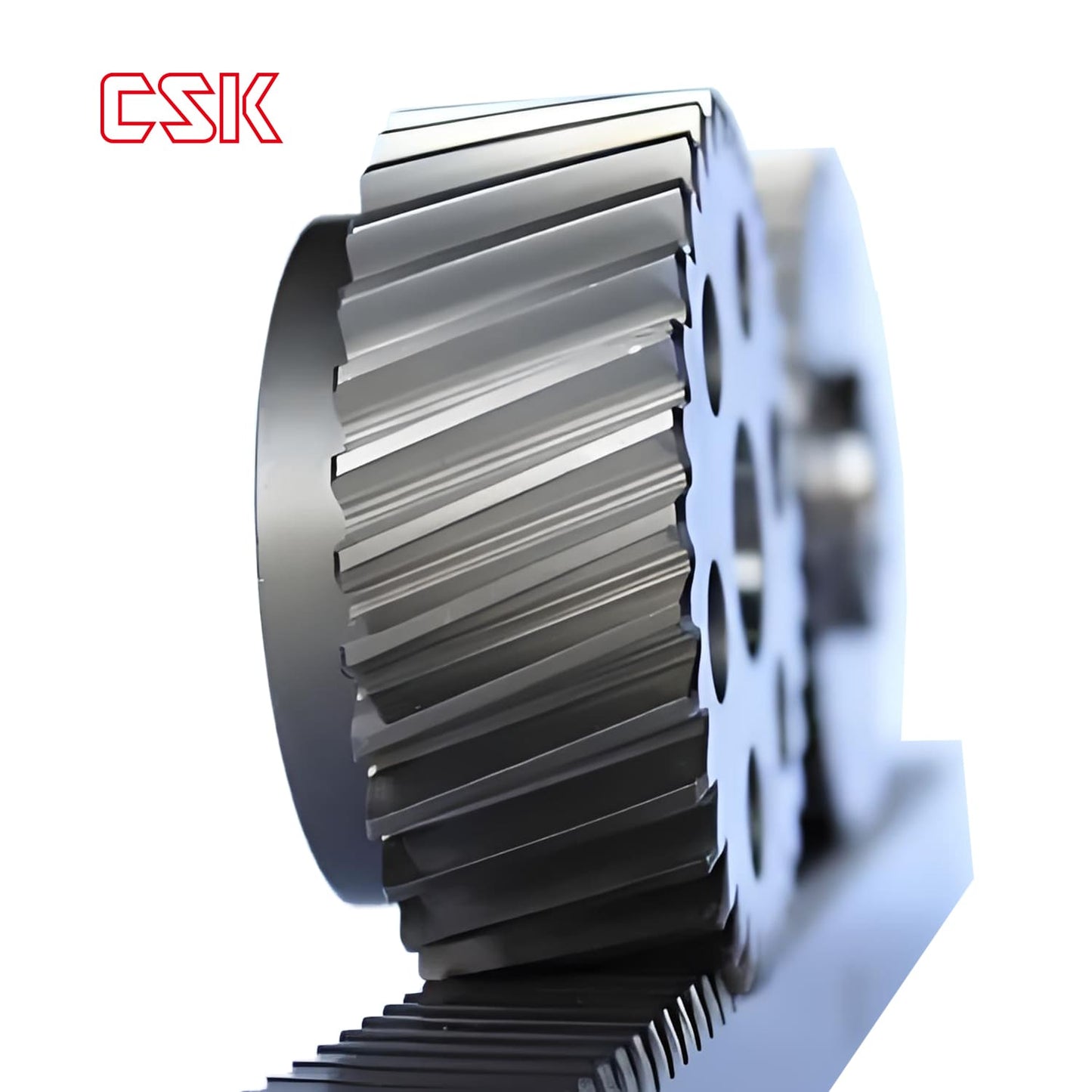

| Type | Spur/Helical Rack |

| Module | 2/3/4/5 |

| Gear Grinding Accuracy | German Standard DIN 8 |

| Material | C45 |

| Hardness | HRC24-27 |

| Heat Treatment | Quenching and Tempering |

Comparación de dureza

Dureza DIN8 HRC24-27, dureza DIN 6 HRC50-55, bastidores de fresado fino y templado. Los bastidores de grado DIN8 y 6 tienen diferencias significativas en dureza y rendimiento.

Ventaja del producto

-

Alta precisión

Los bastidores lineales de grado DIN8 tienen tolerancias de fabricación estrictas para garantizar una forma y un paso de diente precisos, adecuados para aplicaciones de alta precisión.

-

Tratamiento de templado

Después del tratamiento de templado, se mejoran la dureza y la tenacidad de la cremallera lineal, y se mejoran la resistencia al desgaste y la resistencia al impacto.

-

Alta eficiencia de transmisión

Las cremalleras lineales de alta precisión combinadas con los engranajes correspondientes pueden lograr una mayor eficiencia de transmisión y reducir la pérdida de energía.

-

Tratamiento de superficies

Las cremalleras lineales están endurecidas para aumentar la resistencia al desgaste y a la corrosión.

Movimiento lineal de alta precisión

- El motor u otra fuente de energía impulsa el engranaje para girar a través de un dispositivo de transmisión (como un reductor de velocidad).

- A medida que el engranaje gira, los dientes del engranaje entran en contacto con los dientes de la cremallera.

- El movimiento de rotación del engranaje se transmite a la cremallera a través de los dientes, haciendo que la cremallera produzca un movimiento lineal a lo largo de su longitud.

- Equipado con un codificador o sensor para monitorear la posición del rack en tiempo real, se realiza un control de movimiento preciso a través de un sistema de control de retroalimentación.